Introduction

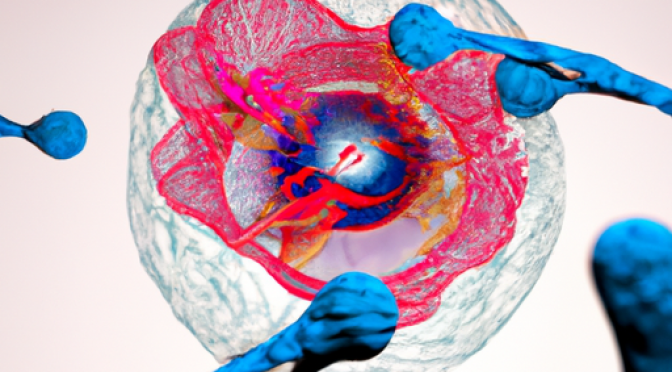

Micro-scale 3D printing has revolutionized various industries by enabling the creation of intricate and precise structures at a miniature level. However, one of the challenges faced in this field is achieving high resolution and capturing fine details in the printed objects. Machine learning, with its ability to analyze complex patterns and make accurate predictions, has emerged as a promising tool to enhance the resolution and detail capabilities of micro-scale 3D printing.

Understanding the Limitations

Before delving into the role of machine learning, it is important to understand the limitations of micro-scale 3D printing. The resolution of a 3D printer is determined by the size of the smallest feature it can accurately reproduce. At the micro-scale, this becomes particularly challenging due to factors such as the nozzle size, material properties, and the precision of the printing process. These limitations often result in loss of fine details and reduced resolution in the final printed object.

The Role of Machine Learning

Machine learning algorithms can play a crucial role in overcoming the limitations of micro-scale 3D printing. By analyzing large datasets of high-resolution 3D models and their corresponding printed outputs, machine learning models can learn the intricate relationships between the input design parameters and the resulting printed object’s resolution and detail level.

Data Collection and Preprocessing

The first step in utilizing machine learning for enhancing micro-scale 3D printing is to collect a diverse dataset of high-resolution 3D models along with their corresponding printed outputs. These models should cover a wide range of geometries, complexities, and desired levels of detail. The collected data then needs to be preprocessed, ensuring that it is properly formatted and tagged with relevant information such as the printing parameters, material properties, and desired resolution.

Feature Extraction and Selection

Once the dataset is ready, the next step is to extract meaningful features from the 3D models. These features can include geometric properties, surface characteristics, and structural attributes. Feature selection techniques can be applied to identify the most relevant features that have a significant impact on the resolution and detail capabilities of the printed objects.

Model Training and optimization/" target="_blank">Optimization

With the dataset and selected features in place, machine learning models can be trained to predict the resolution and detail level of a printed object based on its design parameters. Various algorithms such as regression, decision trees, or neural networks can be employed for this task. The models are trained using the collected dataset, and their performance is optimized through techniques like cross-validation and hyperparameter tuning.

Model Validation and Testing

Once the models are trained and optimized, they need to be validated and tested using new, unseen data. This ensures that the models can generalize well and accurately predict the resolution and detail capabilities of micro-scale 3D printing for a wide range of designs. The performance of the models can be evaluated using metrics such as mean squared error or accuracy.

Benefits and Applications

The integration of machine learning in micro-scale 3D printing can bring several benefits. Firstly, it can significantly improve the resolution and detail capabilities of the printed objects, allowing for the creation of more intricate and precise structures. Secondly, it can reduce the trial-and-error process by providing accurate predictions of the printing outcomes, saving time and resources. Lastly, machine learning can enable automated optimization of the printing parameters, leading to enhanced efficiency and productivity in the manufacturing process.

These advancements in micro-scale 3D printing can have a wide range of applications across industries such as healthcare, electronics, and aerospace. For example, in the healthcare sector, machine learning-assisted micro-scale 3D printing can enable the production of customized medical implants with intricate internal structures, improving patient outcomes.

Conclusion

Machine learning has the potential to revolutionize micro-scale 3D printing by enhancing its resolution and detail capabilities. By leveraging large datasets, extracting meaningful features, and training accurate prediction models, machine learning can overcome the limitations of micro-scale 3D printing and enable the creation of intricate and precise structures at a miniature level. The integration of machine learning in this field opens up new possibilities for various industries and paves the way for advancements in manufacturing technology.